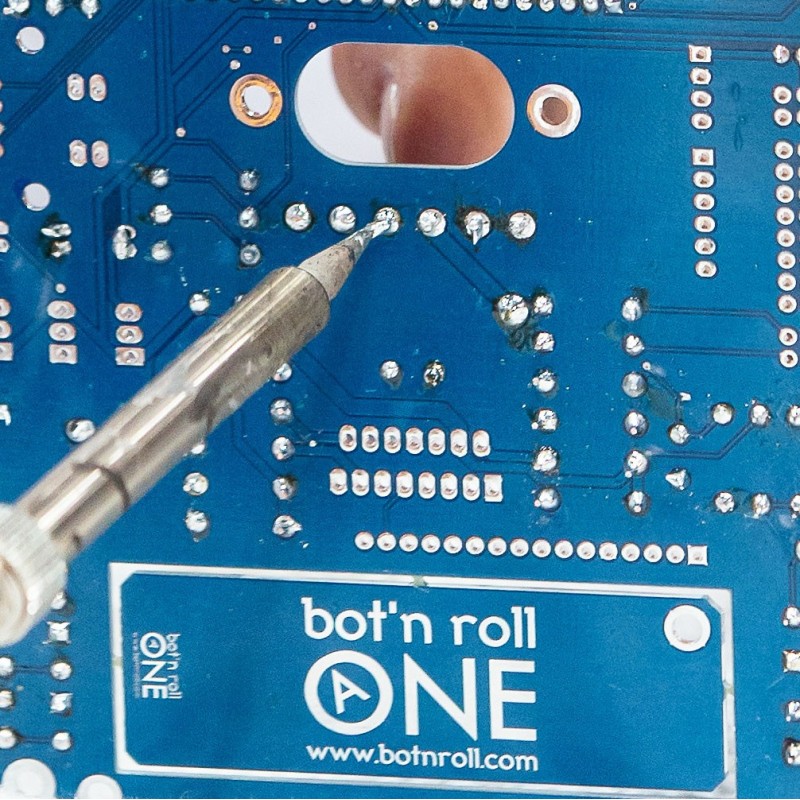

Tips for successfully soldering Bot'n Roll ONE A components! Solving common soldering problems!

The right materials and some skill are the necessary things you need to solder electronic components on a Printed Circuit Board (PCB), this is easier than it seems!

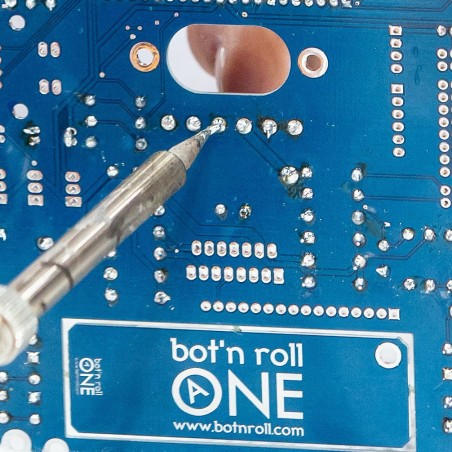

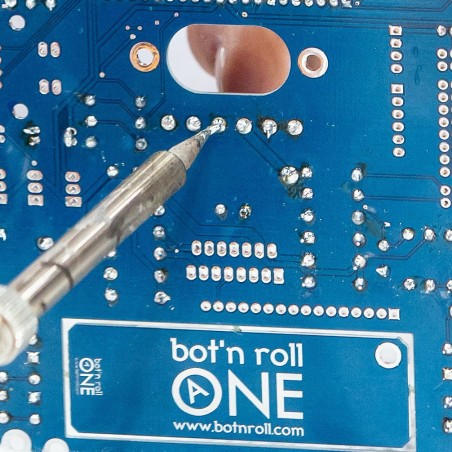

The video demonstrates the soldering process for several components of Bot´n Roll ONE A robot. Watch it carefully!

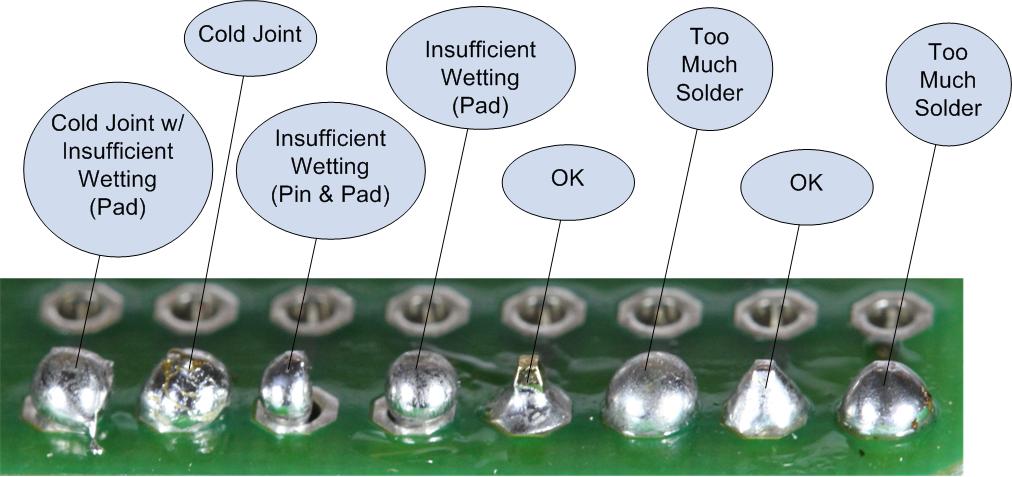

Solder must be added so it fills all the pad on the board and completely wets the pad and the component pin.

You should add the necessary amount of solder to have a similar result as in the next image.

Solder must connect the component to the pad effectively and wetting must be perfect so no air remains inside the joint.

To achieve this, keep the solder melting for 2 or 3 seconds after it liquefies so it fills all the space between the pad and component removing the air from the joint allowing a perfect electrical contact!

Solder must be smooth and shiny… but obviously, you need a good quality solder wire for this to happen.

Clean the iron frequently to prevent debris from accumulating in the weld!

The most common problems found while repairing are related with insufficient temperature that causes a defective electrical contact between the component and the pad.

Cold joints can usually be repaired by simply re-heating the joint with a hot iron until the solder flows. keep the solder melting for 2 or 3 seconds after it liquefies so you have a perfect electrical contact!

You need more time and heat to solder pads connected to ground plane. The pad marked above has a ground connection! The ground plane is a layer of copper that fills the all board and is connected to the battery 0V voltage.

Ambient temperature has a great influence on the soldering process. There are significant differences in soldering during the summer and during the winter! In winter you solder slowly… you need more time for melting the solder wire.

When one add solder until if results in a blob and not a concave surface it causes an excess solder problem.

When two pads are very close and both have too much solder one can easily blend the connections and cause a short-circuit!

Too much solder is solved with the soldering remover! Melt the solder and use the solder pump as demonstrated in the final seconds of the tutorial video.

Long component leads are not a direct problem but a potential risk for short-circuits to occur. Short circuits are the real problem here, they can destroy the board and cause fire!

Trim all leads just at the top of the solder joint using the cutting plier.

Related products

Tips for successfully soldering Bot'n Roll ONE A components! Solving common soldering problems!